| |

|

| |

|

|

| |

| |

| Products |

| |

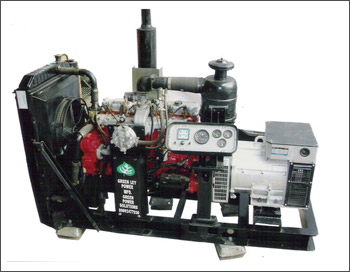

| 1. GAS GENSET : |

| |

| Our Range includes 30 KVA, 40 KVA, 62.5 KVA & 123 KVA which are ideal for Small & Medium Enterprises operating in City Gas Distribution Networks. Our customers include Industries, Residential Buildings & Complexes, Hospitals , Hotels , Factories , Textile Units , Foundries etc. |

| |

| The gas gensets are manufactured using proven , versatile & rugged Ashok Leyland Gas Engines and Reputed make Alternator. They operate at 1500 rpm and are water cooled with built in radiator. They are provided with Anti-Vibration Mounting’s for Engine , Alternator & also separately for complete Genset thus making it nearly zero vibration. It has electronically controlled Governing making it a highly fuel efficient Gas Genset. It is provided with closed loop lambda controlled gas monitoring for emission reduction , thus making it a true ‘ solution 2 pollution ‘ product. |

| |

| These gensets can operate continuously 24 X 7 depending on Load , Fuel & Ambient conditions. They have low maintenance cost with service interval of 1000 Hours compared to 250 Hours incase of Diesel Gensets & other makes of Gas Gensets. Thus reducing down time & also waste of material like engine oil , filters etc.” |

|

|

|

| |

| Top |

| |

| 2. CONTROL PANEL : |

| |

| MANUALLY OPERATED CONTROL PANEL |

| |

| A standard Genset is usually supplied with a manual control panel having fail safe unit, oil pressure guage, coolant temperature guage, battery charging indicator, line voltage indicator, line current indicator etc. In this case, the engine is started from its own control panel and after the rated speed and voltage have been attained the switch in the manual panel is put on to connect the Genset to the load. |

| |

| AUTOMATIC MAINS FAILURE (OPTIONAL) |

| |

AMF panel and generator packages are designed to provide emergency power during a mains supply failure. During operation, the control panel of the AMF monitors the mains entering the building. If a mains failure occurs, the panel will disconnect the mains from the load, the generator is started and its output connected to the load. (The load being appliances, lights, etc in use within the house/office/factory at the time of mains failure).

The generator continues to supply the building until the mains supply returns. The generator then automatically disconnects, stops and the mains is re-connected to the load. The AMF panel reverts to the standby mode ready to respond in the event of another mains failure. |

|

|

|

| |

| Top |

| |

| 3. ACOUSTIC ENCLOSURES (CANOPY) : |

| |

ACOUSTIC ENCLOSURES is not mandatory for Gas Gensets .Where the genset is required to work in noise-sensitive areas, e.g. hospital, hotels, residential districts etc. a canopy can be provided to suit the most stringent noise specifications. Our acoustic enclosures are built to withstand extreme weather conditions.

The acoustic enclosure is manufactured with a steel outer skin, and is lined with fireproof, acoustic material. Each canopy is designed with a panel viewing window. Side-opening access doors are provided. Attenuators are placed on the hot air outlet and cooling air inlet with corresponding weather louvers , allow sufficient airflow for the set operate even under the harshest ambient conditions whilst maintaining specified noise levels without loss of power.

A high efficiency exhaust silencer(s) of the residential type are mounted either on top of, or inside the enclosure, with all internal pipe work including flexible bellows already connected, exhausting to atmosphere. The canopy is finished in epoxy or polyurethane two pack paint. |

|

|

|

| |

| Top |

| |

| 4. GAS TRAINS : |

| |

Piped Natural Gas is available at different pressures & compositions at different locations , for optimal & safe operations gas trains have to be used. A gas train consists of filters, slam-shut off valve, pressure regulator, safety relief valve and flame arrestor.

Filter helps to remove the dust/ dirt particles in the gas, which may damage the regulator parts. The slam shut off valve normally remains open. In case the outlet pressure of the regulator exceeds the permissible limits, the slam shut off valve senses it through the impulse line and instantly shuts off the supply to the downstream system.

The safety relief valve is provided for additional safety. It is to be set at higher pressure than the slam shut off valve pressure so that the safety relief valve will operate only when slam shut off valve fails to operate. The outlet of the safety relief valve is vented well above the roof. |

| |

| Gas Trains are available for Operations from 250 bar to 500 mm WC. |

|

|

|

| |

| Top |

|

|

|

|

|